Project Summary

The Zeb Nickel Project is advancing a nickel sulfide project strategically located in the Bushveld Complex in South Africa. The Zeb Project Contains a historical indicated resource1 of 485.4 million tonnes averaging 0.245% Ni, with an additional Inferred Resource of 1,115.1 million tonnes at 0.248% Ni using a cut-off grade of 0.1% TNi (Total Nickel).

1. The Historical Resource Estimate used categories that conformed to CIM Definition Standards on Mineral Resources and Mineral Reserves (CIM, 2010) at the time of completion of the Historical Resource Estimate. The Historical Resource Estimate has an effective date of March 31, 2012 and estimated an Indicated Resource of 485.4 million tonnes averaging 0.245% Ni, with an additional Inferred Resource of 1,115.1 million tonnes at 0.248% Ni, using a cut-off grade of 0.1% TNi (Total Nickel). The Historical Resource Estimate used a nickel price of US$8.50 per pound or US$18,739.00 per ton. The mineral resources were quoted as TNi and were restricted to mineralization in the “Sulphide Zone”. They were stated as in-situ with no geological losses applied. The mineralization in the Uitloop II body was constrained by a TNi grade-derived envelope. Although the intrusive body is largely coincident with this, there is no uniform geological control on the mineralization across the body.

Additional drilling was determined to be required to further investigate the morphology of the mineralized envelope and to in-fill sparsely-drilled areas. The Company’s drill program planned for 2023 is intended to determine a current estimate of mineral resources on the Zeb Project and the extent to which the Historical Resource Estimate may be considered current. The Historical Resource Estimate is not supported by a compliant NI 43-101 technical report, and the Historical Resource Estimate should not be relied on until it has been verified and supported by a compliant NI 43-101 technical report. Richard Montjoie has supervised the preparation of the scientific and technical contained in this Project Summary and has approved the disclosure herein (other then the historical estimate). Mr. Montjoie is the CEO & VP Exploration of the Company and is not, therefore, independent of the Company. Mr. Montjoie is a registered member of the South African Council for Natural Scientific Professions (SACNASP) membership number 400131/09. Mr. Montjoie holds a M.Sc. in Economic Geology from the University of Witwatersrand, South Africa, and is a Fellow of the Geological Society of South Africa (GSSA).

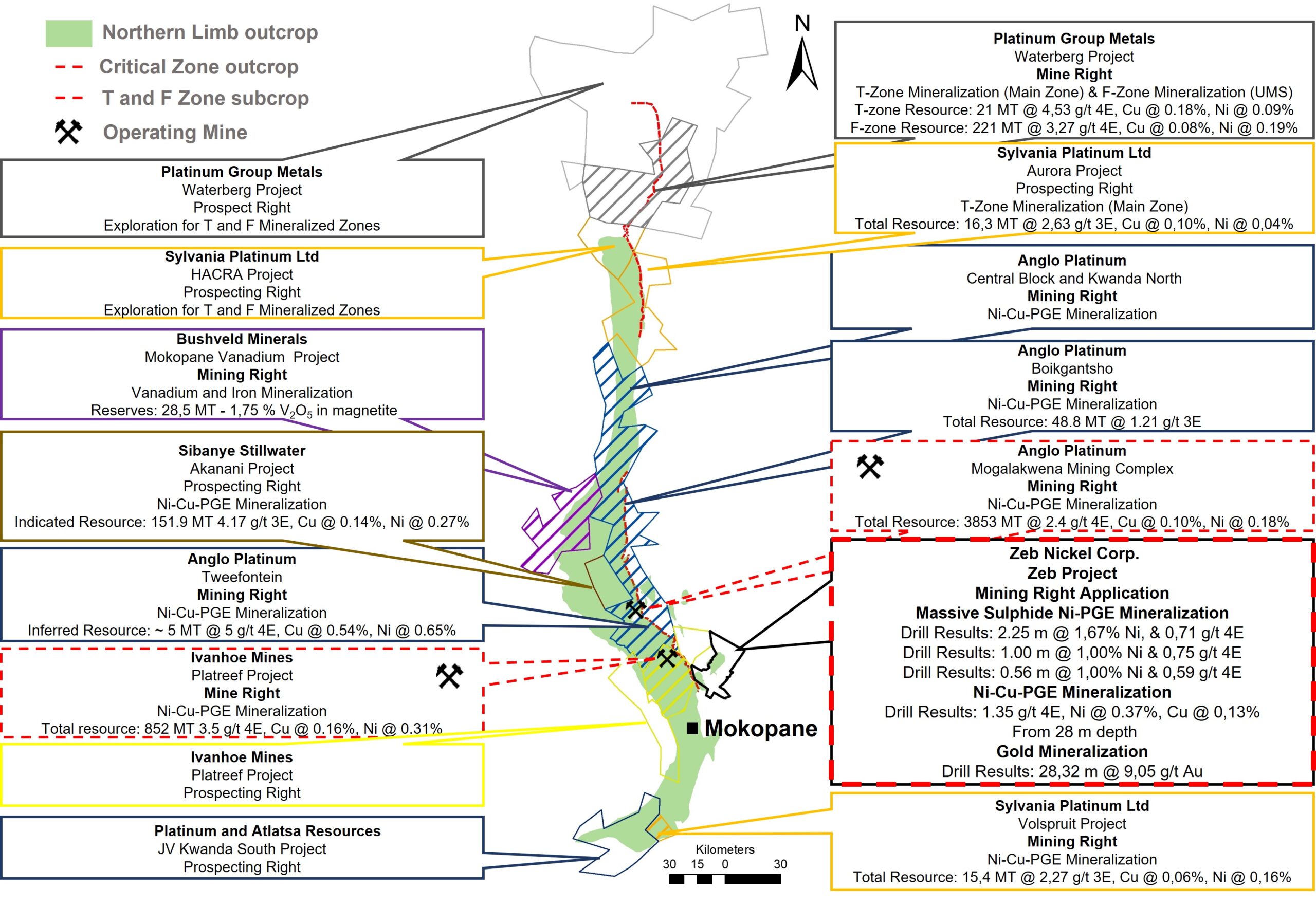

The project is situated in the world-class Platinum Group Element (PGE) and nickel producing region of the Bushveld Complex, located in South Africa. The Bushveld Complex contains over 75% of the world’s platinum reserves, which are usually associated with magmatic nickel deposits. The project is situated in the world-renowned Ni-Cu-PGE producing area of the Northern Limb, which hosts Anglo Platinum’s Mogalakwena mine, the biggest open cast platinum mine in the world, less than 15 km north of the Zeb Nickel project. Another noteworthy neighbor is Ivanhoe’s Platreef Project, situated approximately 5 km north-west of the project. The area is supported by excellent access to infrastructure with road, rail, power, and water, all located nearby or on site.

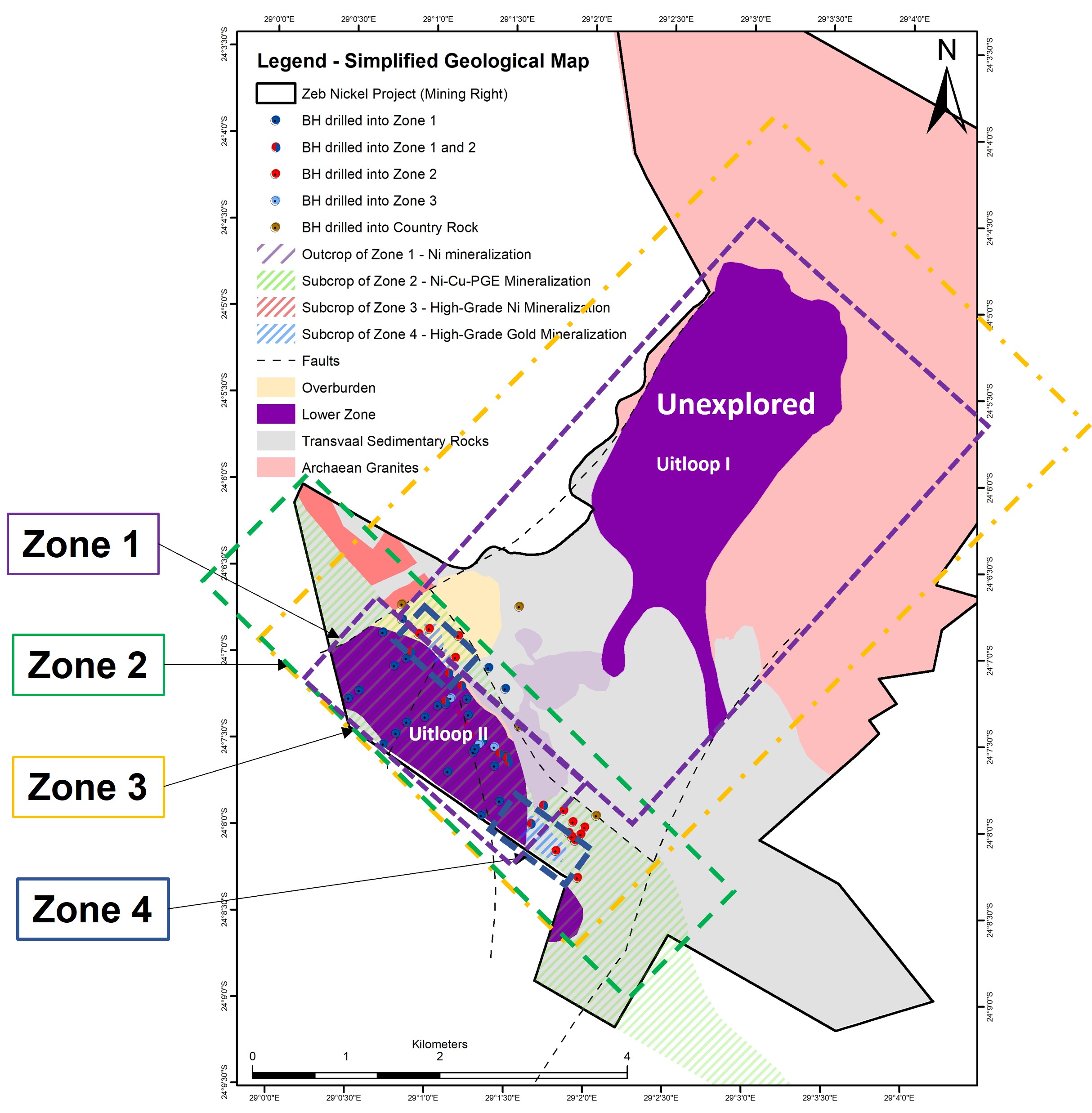

There are four distinct zone areas identified over a strike length of over 5 km on the project, targeting near surface Ni sulfides and high-grade mineralization at a depth. The four zone types identified are:

Zone 1

Disseminated Nickel Sulfide Resource1

A historical Indicated resource1 of 485.4 Mt @ 0.25% Ni and Inferred resources of 1.115 Mt @ 0.25% Ni using a cut-off grade of 0.1% TNi (Total Nickel).

Zone 2

Ni-Cu-PGE Mineralization

Proven strike length of 3,5 km with a mineralized width of 5 to 100 m and extending down to depths in excess of 400 meters. This is the same geological zone that is being exploited at the Anglo American Platinum’s Mogalakwena Mining Complex, and the adjacent Ivanhoe Mines Platreef Project. The mineralized zones remain open along strike and downdip.

Zone 3

Massive Sulfide Footwall Mineralization

Semi-massive to massive Ni-PGE Mineralization (Massive Sulfide Target). Grades of up to 1,7% Ni and 0.69 g/t 3PGE over 2.25 meters were intersected on the Project. Massive sulfide Ni-PGE mineralization may be associated with the Bushveld ultramafic plumbing system interacting with sulfur-rich footwall rocks on the Project Area. The area is geologically similar to the Uitkomst Complex which hosts the Nkomati Nickel Mine – a massive sulfide deposit containing abundant amounts of Ni-Cu-Cr-PGE mineralization.

Zone 4

High-grade Gold Mineralization

High-grade gold mineralization related to remobilized gold from the adjacent Pietersburg Greenstone Belt and hydrothermal activity. Gold grades up to 9 g/t over 30 meters in the south eastern portion of the Project area. In addition, smaller gold-rich intervals were also intersected in the northwest portion of the project area, with the same style of mineralization.

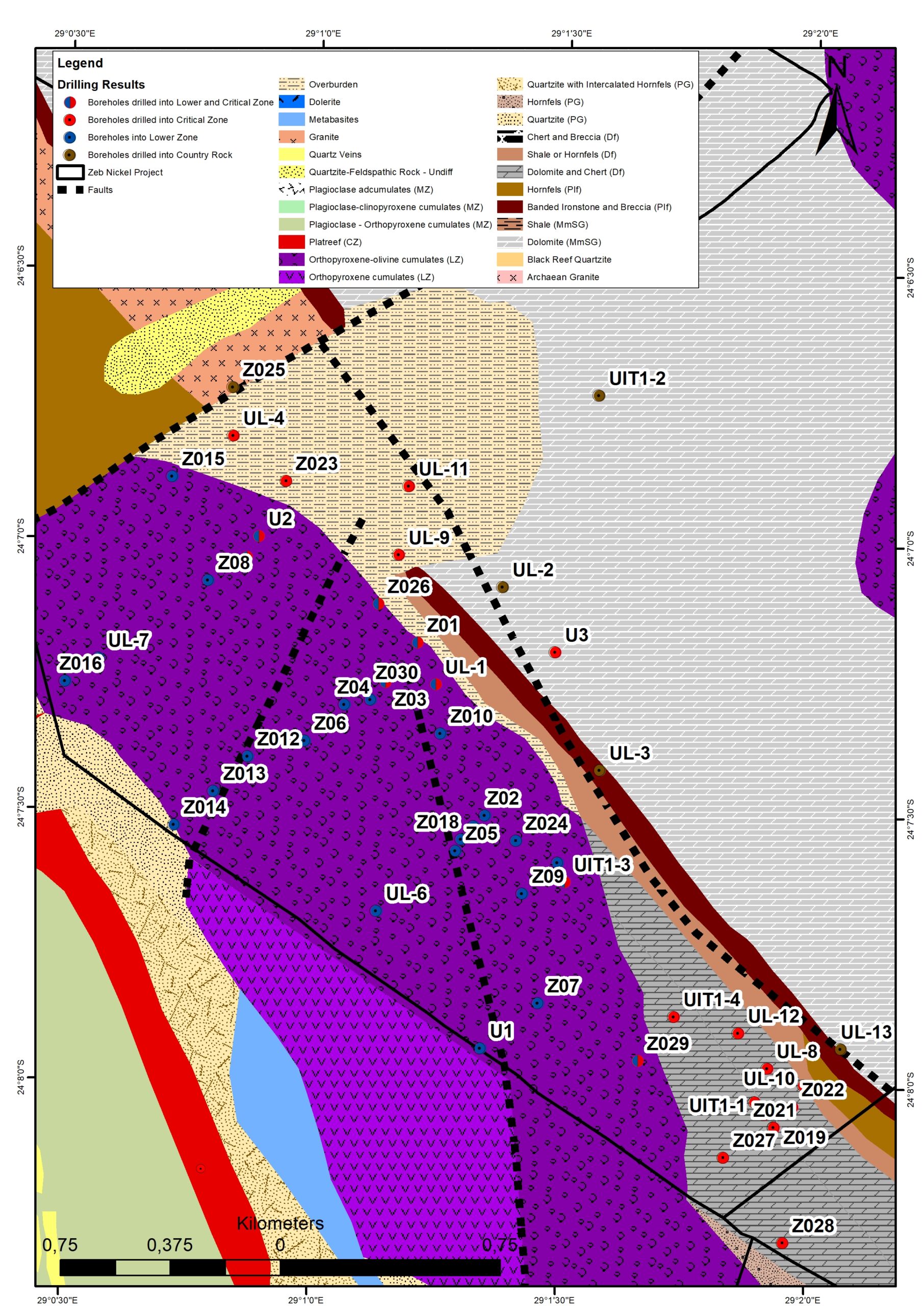

Exploration results from Zeb’s recent two phased drilling campaign are presented in the table below. Drill core diameter for all holes is NQ and drill holes are drilled at an inclination of 50 degrees on an azimuth of approximately 45 degrees.

Richard Montjoie has supervised the preparation of the scientific and technical information contained on this website and has approved the disclosure herein. Mr. Montjoie is the CEO & VP Exploration of the Company and is not, therefore, independent of the Company. Mr. Montjoie is a registered member of the South African Council for Natural Scientific Professions (SACNASP) membership number 400131/09. Mr. Montjoie holds a M.Sc. Honors in Economic Geology from the University of Witwatersrand, South Africa, and is fellow of the Geological Society of South Africa (GSSA).

The analytical work reported on herein was performed by SGS South Africa Proprietary Limited in Randfontein, South Africa, an internationally recognized analytical services provider that is independent of the Company. Samples were analyzed for Ni using a nitric acid leach and sodium peroxide fusion, followed by an ICP-AES finish; and Au, Pt, Pd by lead fusion followed by an ICP-AES finish; and for Rh using palladium collection followed by ICP-OES finish. The sample size varies for the four different zones, however, all samples are quarter core: Zone 1 (“ZEB 1”) – 2 meter samples; Zone 2 – 1 meter samples and 0.50 centimeter samples with increase sulfides; Zone 3 – 0.50 centimeters samples; Zone 4 – 1 meter samples. Samples sizes vary to get better definition on mineralized intervals. The Company has not identified drilling, sampling, recovery or other factors that could materially affect the accuracy or reliability of the data disclosed.

A full Quality Control and Quality Assurance (QA/QC) program was conducted on all assay results, and all reported assays were deemed to be acceptable. The program was designed and implemented by Dr. Matthew McCreesh. The QA/QC program is implemented by using Certified Reference Materials (CRM) to verify Laboratory testing equipment calibration, sample homogenization, repeatability of values and to determine limits of detection. Blanks are inserted to check for sample cross-contamination or instrument contamination. On site sample weights are compared to laboratory sample weights, possible sample swaps are detected when sample weights do not correspond. Field duplicates are pulp samples from the previous assay batches with known analytical results, which are add to the batches and are re-analyzed and in theory should be similar in grade to the previous results. Duplicate samples contain all levels of error: natural variability, field sampling, sample size reduction in the prep laboratory, and subsampling at the pulp, plus the analytical error and analytical precision. A Certified Reference Materials (CRMs) or duplicate sample is inserted per 10 field samples. The CRMs are sourced from AMIS (African Mineral Standards) have been tested on a round robin across 25 or more laboratories. Analytical results received from the laboratory must verified immediately upon arrival. Blank samples reporting grade and standards falling above or below 2 standard deviations should be flagged and re-assayed by the laboratory if necessary. This is to ensure that field and laboratory errors are addressed timeously, and Standard Operating Procedures (SOPs) are reviewed on an ongoing basis as drilling progresses. This limits the incorporation of re-occurring errors into the database and resource estimations. Dr. McCreesh is a registered member of the South African Council for Natural Scientific Professions (SACNASP) membership number 132928. Dr. McCreesh holds a Ph.D. in Geology from the University of Witwatersrand, South Africa, and is member of the Geological Society of South Africa (GSSA).

All Zeb Nickel data was verified before being statistically processed. All data is captured and stored on a cloud based software, this is a centrally managed database containing all aspects of drilling information including logging and assay results. In addition, Zeb Nickel uses ARCGIS, a GIS database system for all spatial information relating to exploration activities. Several other datasets exist including several Excel spreadsheets of information; however, these are derived from the cloud based databases referenced above to ensure that all information is centrally updated and stored.

The data is verified for errors and inconsistencies at each step of handling. Internal check occurs at the project level, where the project geologist or senior exploration geologist, print out hardcopies geological logs and checks the drilled core. The depths of mineralization, sample numbers and widths and lithologies are confirmed. The full process from core logging to data capturing into the database are reviewed on site. Collar positions of a few random selected drill holes are checked in the field during site visit. The data is also rechecked at the stage where it is entered into the 3D-modelling software. In addition, to ongoing data checks by project staff, the senior management and directors of Zeb Nickel have completed spot audits of the data and processing procedures. Audits have also been carried out on the recording of drill hole information, the assay interpretation and final compilation of the information. The individuals in Zeb Nickel’s senior management and certain directors of the Company, who completed the tests and designed the processes, are non-independent mining or geological experts.